Thread Gauge Calibration Service

Thread Gauge Calibration Service

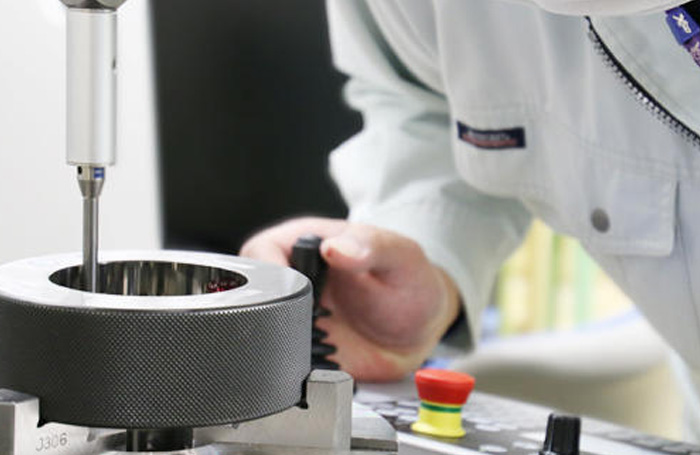

Thread gauge calibration services are specialized services offered by calibration laboratories or metrology service providers to ensure that thread gauges are measuring accurately and consistently.

Calibration of thread gauges involves testing the accuracy of the gauge against a standard of known accuracy. During the calibration process, the thread gauge is tested with the standard to determine whether the gauge is measuring within its specified tolerances. If the gauge is found to be out of tolerance, adjustments can be made to bring the gauge back into calibration.

The calibration process for thread gauges typically involves the following steps:

- Visual inspection: The gauge is inspected for any signs of damage or wear that could affect its accuracy.

- Initial measurement: The gauge is measured to establish a baseline for comparison.

- Calibration: The gauge is tested against a standard of known accuracy to determine its accuracy and identify any deviations.

- Adjustment: If the gauge is found to be out of tolerance, adjustments can be made to bring the gauge back into calibration.

- Final measurement: The gauge is re-measured to verify that it is measuring accurately and consistently.

- Calibration certificate: A calibration certificate is provided that documents the results of the calibration, including the measurements taken and any adjustments made.

Calibration of thread gauges is important to ensure that the measurements taken with the gauge are accurate and consistent. Thread gauges that are out of calibration can lead to incorrect measurements, which can result in defective or non-conforming products and can also compromise the safety and reliability of equipment. It is recommended that thread gauges are calibrated at regular intervals, typically once a year, or more frequently depending on the frequency of use and the requirements of the industry.

Our Products Range

-

Thread Gauges